In today’s manufacturing landscape, visibility is power. Knowing exactly what’s happening on your production lines—at any given moment—can mean the difference between hitting targets or facing costly delays. That’s why MiAssist, developed by Packaging Automation Ltd, is more than just a machine monitoring tool—it’s a real-time operational command centre designed to help manufacturers optimize performance, minimize downtime, and drive efficiency across their heat sealing operations.

What is MiAssist?

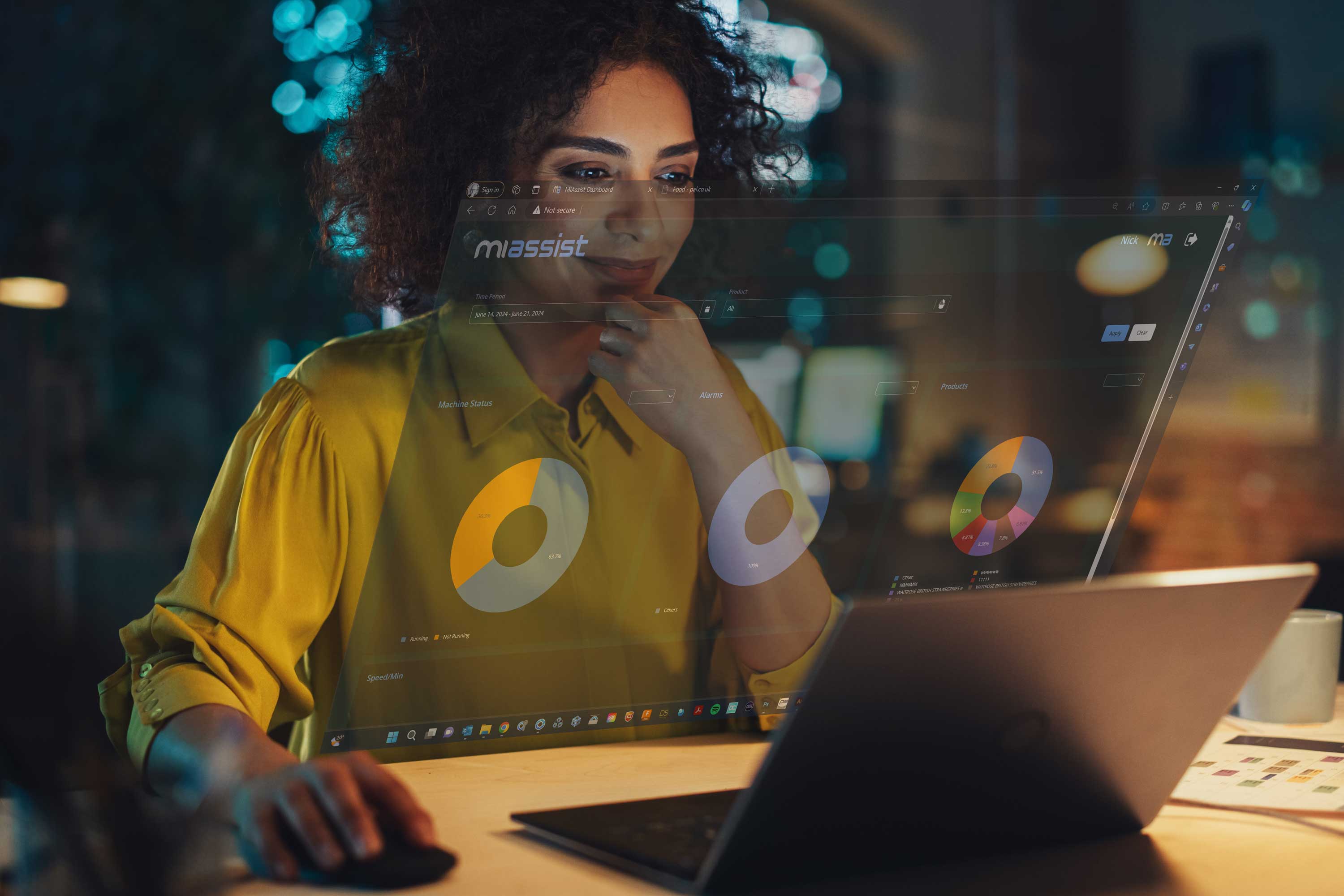

MiAssist is a cloud-based dashboard that connects directly to your production machinery to provide live data feeds and actionable insights. Whether you're managing a single line or multiple sites, MiAssist brings your operations together in one intuitive interface, accessible from anywhere in the world.

At its core, the dashboard shows a live status of each machine, clearly indicating whether it's running or stopped. But it doesn’t stop there—MiAssist is packed with features that turn raw data into operational intelligence.

Key Features & Benefits

✅ Real-Time Machine Status

MiAssist gives you a second-by-second view of every machine on the line. Are they running efficiently? Have any stopped unexpectedly? This immediate insight allows your team to react quickly and reduce unplanned downtime before it impacts your output.

✅ Live OEE Metrics

Overall Equipment Effectiveness (OEE) is the gold standard for measuring manufacturing productivity. MiAssist tracks and displays your OEE in real-time, broken down into availability, performance, and quality. This allows managers to pinpoint issues, track progress, and set tangible goals for continuous improvement.

✅ Remote Accessibility

Whether you're on the factory floor, in the office, or halfway across the globe, MiAssist keeps you connected. The cloud-based platform is accessible from any internet-enabled device, meaning decision-makers no longer need to be physically present to stay informed.

✅ Downtime Monitoring & Root Cause Analysis

Knowing a machine stopped is only the first step. MiAssist helps you understand why it stopped by logging downtime events and reasons. This insight supports more effective maintenance planning and helps eliminate recurring issues.

✅ Historical Data & Reporting

Beyond real-time monitoring, MiAssist provides access to historical performance data. Custom reports can be generated to track trends over time, support audits, and inform strategic decisions.

✅ Improved Maintenance Planning

By identifying performance anomalies and recurring stoppages early, maintenance teams can move from reactive fixes to proactive servicing—saving time, reducing costs, and extending machine life.

Why MiAssist Matters

In manufacturing, time is money—and wasted time means lost revenue. MiAssist empowers teams to stay agile, make informed decisions faster, and improve operational efficiency with a data-driven approach. The dashboard becomes a shared source of truth, uniting production, engineering, and management under a single, accurate view of what's really happening on the floor.

- For businesses seeking a competitive edge, MiAssist offers:

- Increased machine uptime

- Reduced waste

- Faster response to issues

- Greater accountability

- Better team communication

Final Thoughts

As the manufacturing world leans further into Industry 4.0, tools like MiAssist are no longer optional—they’re essential. By turning real-time machine data into actionable insights, MiAssist helps your operation move from guesswork to precision, from reactive to proactive, and from good to great.

Whether you're scaling production, trying to meet tight deadlines, or just want a clearer picture of how your machines are performing, MiAssist gives you the visibility, control, and confidence to do it better.

Was this article helpful?

That’s Great!

Thank you for your feedback

Sorry! We couldn't be helpful

Thank you for your feedback

Feedback sent

We appreciate your effort and will try to fix the article